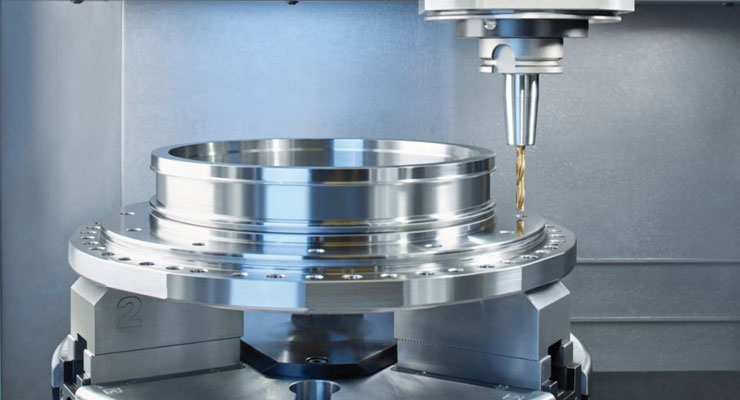

Drilling is a critical process in various industries, including manufacturing. It involves creating holes or shafts in different materials, such metal. The choice of drilling method depends on the material being drilled, the purpose of the drilling, and the required precision and efficiency.

Mobile and stationary rigs for various drilling applications.

Include truck-mounted, skid-mounted, and portable rigs.

Different types for various materials, including carbide and steel bits.

Connect the drill bit to the drilling rig.

Provide the necessary length and strength for deep drilling.

Used in percussion and DTH drilling.

Provide the impact force to break up material.

Used in rotary drilling to lubricate the bit and remove cuttings.

Essential for maintaining borehole stability.

Ensure precision and safety during drilling operations.

Include systems for monitoring pressure, torque, and depth.