Leading Rebar Coupler Manufacturer in India

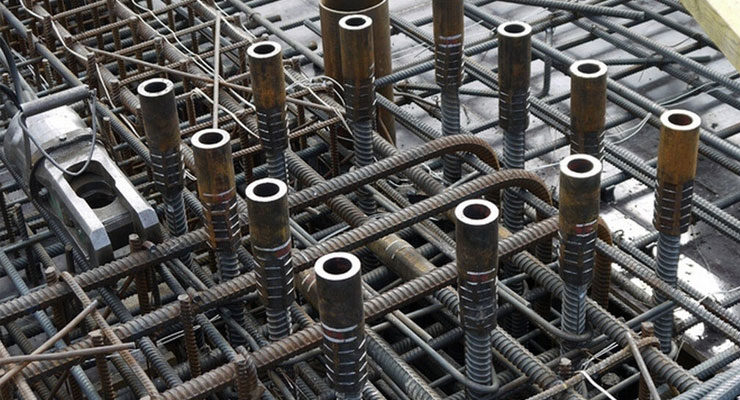

Aspal Engineering is a premier Rebar Coupler Manufacturer in India, specializing in high-strength mechanical splicing systems that replace traditional lap splicing. Our couplers deliver unmatched tensile capacity, ensure safer construction, and save valuable time on-site. From high-rise towers to metro projects and infrastructure development, our products are trusted nationwide for reliability, strength, and compliance with global standards.

Couplers for Construction

1. Rebar Couplers:

Used to connect reinforcing bars in concrete structures.

Provide a mechanical connection that transfers load between rebar segments.

Types include:

Parallel Threaded Couplers: Have matching threads on the ends of the rebar and the coupler, providing a strong and precise connection.

Tapered Threaded Couplers: Feature tapered threads that enhance the grip as the coupler is tightened.

Selection Criteria for Couplers

1. Material Compatibility:

Ensure the coupler material is compatible with the connected elements to prevent corrosion and degradation.

Common materials include steel, stainless steel, and specialized alloys.

2. Load Requirements:

Choose right size of couplers that can handle the specific load and stress conditions of the application.

Consider factors such as tensile strength, shear strength, and fatigue resistance.

3. Ease of Installation:

Select couplers that are easy to install, especially in tight or difficult-to-access locations.

Some couplers require specialized tools or equipment for installation.

4. Regulatory Compliance:

Ensure the couplers meet relevant construction codes and standards, such as ASTM, ACI, and ISO standards.

Compliance with regulations ensures safety and reliability.

5. Environmental Conditions:

Consider the environmental conditions the couplers will be exposed to, such as temperature, humidity, and chemical exposure.

Choose couplers with appropriate coatings or materials to withstand these conditions.

Types of Rebar Couplers We Manufacture

- Parallel Threaded Rebar Couplers – Standard splicing with consistent performance.

- Taper Threaded Rebar Couplers – Extra pull-out resistance for critical structures.

- Reducer Couplers – Seamlessly connect rebars of different diameters.

- Weldable Couplers – Ideal for customized welding solutions onsite.

Applications of Our Rebar Couplers in India

- Metro & flyover projects

- Commercial & residential high-rise buildings

- Dams, bridges & highways

- Industrial foundations & power plants

- Water infrastructure & urban development

Advantages Over Traditional Lap Splicing

- Reduces bar congestion in reinforced concrete

- Saves steel, space, and overall project cost

- Provides full structural continuity

- Faster & safer installation on site

- Environmentally friendly with less wastage

About Aspal Engineering

At Aspal Engineering, we combine advanced technology with strict quality control to deliver the most reliable mechanical couplers. Recognized as one of the top Rebar Coupler Manufacturers in India, we supply products to leading construction firms, government infrastructure projects, and private developers. Our mission is to enhance safety, efficiency, and sustainability in construction through innovative rebar splicing solutions.

Frequently Asked Questions (FAQ)

Q1: What makes Aspal Engineering a leading Rebar Coupler Manufacturer in India?

We are IS 16172 certified, provide a wide range of coupler types, and ensure quality through rigorous testing and international standards compliance.

Q2: Why should I use rebar couplers instead of lap splicing?

Rebar couplers reduce congestion, save steel, and provide stronger, more reliable splicing compared to traditional lap joints.

Q3: What sizes of rebar couplers are available?

We manufacture couplers ranging from 12mm to 40mm, including customized options.

Q4: Are your rebar couplers suitable for large infrastructure projects?

Yes, our couplers are widely used in metros, bridges, dams, power plants, and high-rise construction across India.

Q5: Do you provide delivery outside India?

Yes, Aspal Engineering not only supplies across India but also exports globally with reliable shipping and technical support.